EMASTERBATCHES.COM prides being India’s First and Only Online Store for Masterbatches. The pioneering initiative has been made by Prayag Polytech Pvt Ltd, a leader in plastic masterbatches industry in India and abroad for over 19 Years now. Our aim is to revolutionise the way in which the masterbatches are being offered to the end customer, thus bringing in a paradigm shift in customer's buying experience.

Monday, 12 September 2016

Friday, 5 August 2016

Tuesday, 5 July 2016

Blow Tank Industry Event Prayag Masterbatches

#Charcha - a knowledge sharing Platform for plastic Industry - An initiave by #Prayag Polytech pvt ltd. First Event organised on 13th June 2016 focussing on #BlowTank industry. We thank all the guests for making it to the event on a short notice and making the event a great success. We appreciate your support and we look forward to your continued patronage and guidance in future as well.

Friday, 20 May 2016

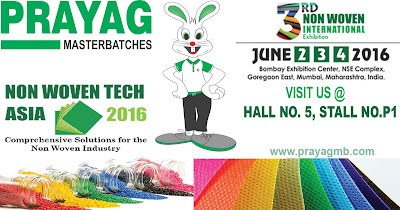

Non Woven Tech Asia 2016

We are delighted to inform you that Prayag Masterbatches participating in 3rd #NonWoven Internatianal Exhibition 2016 at Bombay Exhibiton Center, NSE Complex, Goregaon East,Mumbai, Maharashtra, India.

2nd to 4th June, 2016

We invite you to visit us at Hall No. 5, Stall No. P1

#NonWovenTechAsia2016

#Prayag #Masterbatches

www.prayagmb.com

www.emasterbatches.com

2nd to 4th June, 2016

We invite you to visit us at Hall No. 5, Stall No. P1

#NonWovenTechAsia2016

#Prayag #Masterbatches

www.prayagmb.com

www.emasterbatches.com

Monday, 2 May 2016

Expo Plast Peru 3rd to 6th May 2016, Prayag Masterbatches

We are delighted to inform you that we are participating in

#ExpoPlastPeru 3rd to 6th May 2016

We invite you to visit us at Stall no. S-40 & S-41

#Prayag #Masterbatches

www.prayagmb.com

www.emasterbatches.com

#ExpoPlastPeru 3rd to 6th May 2016

We invite you to visit us at Stall no. S-40 & S-41

#Prayag #Masterbatches

www.prayagmb.com

www.emasterbatches.com

Monday, 11 April 2016

7th Plasto 2016

We are delighted to inform you that we are participating in

7th #Plasto 2016 at Autocluster Exhibition Center

Chinchwad, Pune. 14th to 17th April, 2016

We invite you to visit us at Hall No. B, Stall No. 8

#Prayag #Masterbatches

http://bit.ly/prayagmb

http://bit.ly/emasterbatches

7th #Plasto 2016 at Autocluster Exhibition Center

Chinchwad, Pune. 14th to 17th April, 2016

We invite you to visit us at Hall No. B, Stall No. 8

#Prayag #Masterbatches

http://bit.ly/prayagmb

http://bit.ly/emasterbatches

Thursday, 7 April 2016

Friday, 1 April 2016

P4 Expo India at Greater Noida 5 - 8 April 2016

We are delighted to inform you that we are participating in #P4Expo India at Greater Noida 5 - 8 April 2016International Trade Show and Conference on Plastics, Petrochemicals, Printing and Packaging IndustriesWe invite you to visit us at our stall.

#Prayag #Masterbatches

http://goo.gl/VzdCHF

#Prayag #Masterbatches

http://goo.gl/VzdCHF

Sunday, 27 March 2016

P4 Expo India Greater Noida 5 - 8 April 2016

We wish to inform you that we are participating in #P4Expo

India Greater Noida 5 - 8 April 2016

International Trade Show and Conference on Plastics, Petrochemicals, Printing and Packaging Industries #Prayag #Masterbatches

http://goo.gl/VzdCHF

India Greater Noida 5 - 8 April 2016

International Trade Show and Conference on Plastics, Petrochemicals, Printing and Packaging Industries #Prayag #Masterbatches

http://goo.gl/VzdCHF

Saturday, 19 March 2016

Masterbatch Manufacturer and Supplier in India, Prayag Masterbatches

Established in 1996 at New Delhi India, PRAYAG POLYTECH PVT LTD has been growing exponentially with a CAGR of over 50% in the last 5 years. Prayag today, thus has grown to become the Leading and the most Advanced manufacturer of Colour and Additive masterbatches from India.

The company is growing from strength to strength with the help of its strong R&D division to develop products for new applications. Some of the advance d equipments being used in Prayag’s QC and R&D lab include DSC, TGA, FTIR, FPV testing machines, Spectrophotometers, QUV Accelerated Weathering Tester, UV Testing Machine etc

Prayag with its proven range of masterbatches for some of the most critical applications like Synthetic Fibres (Non Wovens, Turf, Textiles, Carpet), Single Pigment Concentrates( SPC/MOC), CPP, BOPP etc, has established it’s credentials as a Knowledge Player in the field of masterbatches.

Prayag’s Three Production facilities at Bhiwadi, Rajasthan India, with a production capacity of 50,000 MT per annum and multiple dedicated lines for each colour, ensure faster deliveries, flexibility and zero contamination.

We pride to have invested in pilot plants for end mpulding processwhich includes Rotational Moulding, Blow Moulding, Fibre extrion, monolyer film, Multilayer film, PET Injection Blow Moulding. These pilot plants provide us the ability to understand and provide more accurate solutions to our customers, by being able to simulate their process requirements on our inhouse Pilot plants.

With its focus on Quality, Consistency, Competitive Pricing and Outstanding Service- Prayag has fast established its presence across the world, with channel partners present locally across 80 Countries spanning The Americas, Europe, Africa and Australasia. As a result of it, today 80% of the company’s revenue comes from Exports.

With an experience of matching over 10000 shades, Prayag has developed the unmatched capability to custom match shades with utmost precision and accuracy. Prayag has also developed the capability to work with most of the polymer types and offers masterbatches with base carrier resin as PE as well as PP, PET, HIPS, GPPS, PBT, Nylon 66, EVA etc.

Prayag offers complete range of products for all major applications like Food and industrial Packaging, Textiles, Household products, Agriculture, Automotive, Consumer goods, Healthcare etc.

Company is continuously expanding its production capacity and encourage more channel partners to help us further expand across the world.

The company is growing from strength to strength with the help of its strong R&D division to develop products for new applications. Some of the advance d equipments being used in Prayag’s QC and R&D lab include DSC, TGA, FTIR, FPV testing machines, Spectrophotometers, QUV Accelerated Weathering Tester, UV Testing Machine etc

Prayag with its proven range of masterbatches for some of the most critical applications like Synthetic Fibres (Non Wovens, Turf, Textiles, Carpet), Single Pigment Concentrates( SPC/MOC), CPP, BOPP etc, has established it’s credentials as a Knowledge Player in the field of masterbatches.

Prayag’s Three Production facilities at Bhiwadi, Rajasthan India, with a production capacity of 50,000 MT per annum and multiple dedicated lines for each colour, ensure faster deliveries, flexibility and zero contamination.

We pride to have invested in pilot plants for end mpulding processwhich includes Rotational Moulding, Blow Moulding, Fibre extrion, monolyer film, Multilayer film, PET Injection Blow Moulding. These pilot plants provide us the ability to understand and provide more accurate solutions to our customers, by being able to simulate their process requirements on our inhouse Pilot plants.

With its focus on Quality, Consistency, Competitive Pricing and Outstanding Service- Prayag has fast established its presence across the world, with channel partners present locally across 80 Countries spanning The Americas, Europe, Africa and Australasia. As a result of it, today 80% of the company’s revenue comes from Exports.

With an experience of matching over 10000 shades, Prayag has developed the unmatched capability to custom match shades with utmost precision and accuracy. Prayag has also developed the capability to work with most of the polymer types and offers masterbatches with base carrier resin as PE as well as PP, PET, HIPS, GPPS, PBT, Nylon 66, EVA etc.

Prayag offers complete range of products for all major applications like Food and industrial Packaging, Textiles, Household products, Agriculture, Automotive, Consumer goods, Healthcare etc.

Company is continuously expanding its production capacity and encourage more channel partners to help us further expand across the world.

Wednesday, 16 March 2016

Tuesday, 15 March 2016

Complete range of Color, UV, Additive, Black, White and Mono Concentrate/ SPC Masterbatches.

Complete range of Color, UV, Additive, Black, White and Mono Concentrate/ SPC Masterbatches.

First And Only Masterbatch manufacturing company to be recognised as a TRADING HOUSE by the Government of India, for its contribution to Exports. Fastest Growing Masterbatch Company from India with CAGR >50% over the last 5 years

Products for all Plastic Conversion processes like- CPP, BOPP, Blown Films, Extrusion Pipe, Injection Moulding, Blow Moulding, Rotomoulding, Raffia etc.

ISO 9001:2008 certified by Joint Accredition System of Australia & New Zealand ( JAZ-ANZ)

http://bit.ly/prayagmb

http://bit.ly/emasterbatches

First And Only Masterbatch manufacturing company to be recognised as a TRADING HOUSE by the Government of India, for its contribution to Exports. Fastest Growing Masterbatch Company from India with CAGR >50% over the last 5 years

Products for all Plastic Conversion processes like- CPP, BOPP, Blown Films, Extrusion Pipe, Injection Moulding, Blow Moulding, Rotomoulding, Raffia etc.

ISO 9001:2008 certified by Joint Accredition System of Australia & New Zealand ( JAZ-ANZ)

http://bit.ly/prayagmb

http://bit.ly/emasterbatches

Friday, 11 March 2016

Monday, 7 March 2016

Friday, 4 March 2016

Masterbatch manufacturer in India, Masterbatch Supplier

About Prayag

India’s leading supplier of Masterbatches since 1996

Headquartered at New Delhi with Three manufacturing facilities in total of 25,000 sqm area at Bhiwadi, Rajasthan, India Cumulative Production Capacity of 50,000 MT Per Annum

Global Presence with channel partners in 80 Countries across all the five continents.

Complete range of Color, UV, Additive, Black, White and Mono Concentrate/ SPC Masterbatches

First And Only Masterbatch manufacturing company to be recognised as a TRADING HOUSE by the Government of India, for its contribution to Exports. Fastest Growing Masterbatch Company from India with CAGR >50% over the last 5 years

Products for all Plastic Conversion processes like- CPP, BOPP, Blown Films, Extrusion Pipe, Injection Moulding, Blow Moulding, Rotomoulding, Raffia etc.

ISO 9001:2008 certified by Joint Accredition System of Australia & New Zealand ( JAZ-ANZ)

Established in 1996 at New Delhi India, PRAYAG POLYTECH PVT LTD has been growing exponentially with a CAGR of over 50% in the last 5 years. Prayag today, thus has grown to become the Leading and the most Advanced manufacturer of Colour and Additive masterbatches from India.

The company is growing from strength to strength with the help of its strong R&D division to develop products for new applications. Some of the advance d equipments being used in Prayag’s QC and R&D lab include DSC, TGA, FTIR, FPV testing machines, Spectrophotometers, QUV Accelerated Weathering Tester, UV Testing Machine etc

Prayag with its proven range of masterbatches for some of the most critical applications like Synthetic Fibres (Non Wovens, Turf, Textiles, Carpet), Single Pigment Concentrates( SPC/MOC), CPP, BOPP etc, has established it’s credentials as a Knowledge Player in the field of masterbatches.

Prayag’s Three Production facilities at Bhiwadi, Rajasthan India, with a production capacity of 50,000 MT per annum and multiple dedicated lines for each colour, ensure faster deliveries, flexibility and zero contamination.

We pride to have invested in pilot plants for end mpulding processwhich includes Rotational Moulding, Blow Moulding, Fibre extrion, monolyer film, Multilayer film, PET Injection Blow Moulding. These pilot plants provide us the ability to understand and provide more accurate solutions to our customers, by being able to simulate their process requirements on our inhouse Pilot plants.

With its focus on Quality, Consistency, Competitive Pricing and Outstanding Service- Prayag has fast established its presence across the world, with channel partners present locally across 80 Countries spanning The Americas, Europe, Africa and Australasia. As a result of it, today 80% of the company’s revenue comes from Exports.

With an experience of matching over 10000 shades, Prayag has developed the unmatched capability to custom match shades with utmost precision and accuracy. Prayag has also developed the capability to work with most of the polymer types and offers masterbatches with base carrier resin as PE as well as PP, PET, HIPS, GPPS, PBT, Nylon 66, EVA etc.

Prayag offers complete range of products for all major applications like Food and industrial Packaging, Textiles, Household products, Agriculture, Automotive, Consumer goods, Healthcare etc.

Company is continuously expanding its production capacity and encourage more channel partners to help us further expand across the world.

The Production Lines include:

Production using most proven technologies like Twin Screw Extruders and Continuous Mixer (LCM) technology, procured from the most renowned suppliers.

High speed mixers for uniform pre-mixing of the raw material

High accuracy computerized feeding systems to ensure high consistency on formulation

Compartmented machines and Advanced dust collection system to ensure cleanliness and avoid contamination

Automatic weighing and bagging systems to avoid human errors and to facilitate faster packaging.

Computerized inventory management system for better management of raw materials and finished goods inventory

Separate facility for manufacturing Black Masterbatches to avoid any cross contamination.

High speed underwater pelletizers as well as Strand pelletisers - to supply as per customer requirement and be able best utilise production capability

As a continuous process to improve our capacity and quality, new machines and technology are being added on a regular basis.

Achievements

The efforts made by Prayag have been well recognised by the industry and the government alike:

The First and the Only Master Batch Company so far to be recognised by the Government of India with the status of "Trading House" for its contribution to exports.

Awarded "Top Exporter of Master Batches from India" as the highest recognition for Exports for the year 2011-12 and 2012-13 by the PLEX COUNCIL (Plastic Export Promotion Council, Government Of India).

Gold Trophy for "HIGHEST CAGR during 2008-2011" in Exports of Masterbatches by PLASTINDIA Foundation.

The company is ISO 9001:2008 certified by Joint Accredition System of Australia & New Zealand (JAS-ANZ) for adhering to stringent quality standards.

http://goo.gl/VzdCHF

http://goo.gl/P0SjrY

India’s leading supplier of Masterbatches since 1996

Headquartered at New Delhi with Three manufacturing facilities in total of 25,000 sqm area at Bhiwadi, Rajasthan, India Cumulative Production Capacity of 50,000 MT Per Annum

Global Presence with channel partners in 80 Countries across all the five continents.

Complete range of Color, UV, Additive, Black, White and Mono Concentrate/ SPC Masterbatches

First And Only Masterbatch manufacturing company to be recognised as a TRADING HOUSE by the Government of India, for its contribution to Exports. Fastest Growing Masterbatch Company from India with CAGR >50% over the last 5 years

Products for all Plastic Conversion processes like- CPP, BOPP, Blown Films, Extrusion Pipe, Injection Moulding, Blow Moulding, Rotomoulding, Raffia etc.

ISO 9001:2008 certified by Joint Accredition System of Australia & New Zealand ( JAZ-ANZ)

Established in 1996 at New Delhi India, PRAYAG POLYTECH PVT LTD has been growing exponentially with a CAGR of over 50% in the last 5 years. Prayag today, thus has grown to become the Leading and the most Advanced manufacturer of Colour and Additive masterbatches from India.

The company is growing from strength to strength with the help of its strong R&D division to develop products for new applications. Some of the advance d equipments being used in Prayag’s QC and R&D lab include DSC, TGA, FTIR, FPV testing machines, Spectrophotometers, QUV Accelerated Weathering Tester, UV Testing Machine etc

Prayag with its proven range of masterbatches for some of the most critical applications like Synthetic Fibres (Non Wovens, Turf, Textiles, Carpet), Single Pigment Concentrates( SPC/MOC), CPP, BOPP etc, has established it’s credentials as a Knowledge Player in the field of masterbatches.

Prayag’s Three Production facilities at Bhiwadi, Rajasthan India, with a production capacity of 50,000 MT per annum and multiple dedicated lines for each colour, ensure faster deliveries, flexibility and zero contamination.

We pride to have invested in pilot plants for end mpulding processwhich includes Rotational Moulding, Blow Moulding, Fibre extrion, monolyer film, Multilayer film, PET Injection Blow Moulding. These pilot plants provide us the ability to understand and provide more accurate solutions to our customers, by being able to simulate their process requirements on our inhouse Pilot plants.

With its focus on Quality, Consistency, Competitive Pricing and Outstanding Service- Prayag has fast established its presence across the world, with channel partners present locally across 80 Countries spanning The Americas, Europe, Africa and Australasia. As a result of it, today 80% of the company’s revenue comes from Exports.

With an experience of matching over 10000 shades, Prayag has developed the unmatched capability to custom match shades with utmost precision and accuracy. Prayag has also developed the capability to work with most of the polymer types and offers masterbatches with base carrier resin as PE as well as PP, PET, HIPS, GPPS, PBT, Nylon 66, EVA etc.

Prayag offers complete range of products for all major applications like Food and industrial Packaging, Textiles, Household products, Agriculture, Automotive, Consumer goods, Healthcare etc.

Company is continuously expanding its production capacity and encourage more channel partners to help us further expand across the world.

The Production Lines include:

Production using most proven technologies like Twin Screw Extruders and Continuous Mixer (LCM) technology, procured from the most renowned suppliers.

High speed mixers for uniform pre-mixing of the raw material

High accuracy computerized feeding systems to ensure high consistency on formulation

Compartmented machines and Advanced dust collection system to ensure cleanliness and avoid contamination

Automatic weighing and bagging systems to avoid human errors and to facilitate faster packaging.

Computerized inventory management system for better management of raw materials and finished goods inventory

Separate facility for manufacturing Black Masterbatches to avoid any cross contamination.

High speed underwater pelletizers as well as Strand pelletisers - to supply as per customer requirement and be able best utilise production capability

As a continuous process to improve our capacity and quality, new machines and technology are being added on a regular basis.

Achievements

The efforts made by Prayag have been well recognised by the industry and the government alike:

The First and the Only Master Batch Company so far to be recognised by the Government of India with the status of "Trading House" for its contribution to exports.

Awarded "Top Exporter of Master Batches from India" as the highest recognition for Exports for the year 2011-12 and 2012-13 by the PLEX COUNCIL (Plastic Export Promotion Council, Government Of India).

Gold Trophy for "HIGHEST CAGR during 2008-2011" in Exports of Masterbatches by PLASTINDIA Foundation.

The company is ISO 9001:2008 certified by Joint Accredition System of Australia & New Zealand (JAS-ANZ) for adhering to stringent quality standards.

http://goo.gl/VzdCHF

http://goo.gl/P0SjrY

Subscribe to:

Posts (Atom)